Freight’s Double Problem—and the On-Trailer Answer

Freight has a double problem. The cost of coordination creates opportunities for theft, and theft, in turn, increases the cost of coordination. As processes strain under speed and volume, teams rely more on judgment and improvisation. That’s when mistakes creep in, and it’s also when organized theft thrives.

Consider this familiar scenario: It’s 7:12 a.m. at Gate 3. Steve pulls up with his tractor; the paperwork pinball has been going since dawn. Broker emails, updated PDFs, a phone that won’t stop. The line’s growing, the system is lagging, and Lina wants the dock back on schedule, so she does what busy yards do under pressure: she waves Steve through.

Lucky break—this time it really was Steve.

Down the road, a meat processor in Tennessee wasn’t as lucky: a fake trucking company picked up ~80,000 lbs of beef (≈$350,000) and vanished. You know these stories. They’re not one-offs; they’re part of a wider surge in identity-based theft and fictitious pickups across North America.

In both cases, the opening is the same: verifying who’s allowed to act costs time and attention when the yard is under pressure. So decisions get simplified, exceptions get waved through, and trust fills the gap.

When incidents happen, the usual response is to add more checks, calls, alerts, and audits — which raises the cost of coordination even further, ensuring the same moment will break again tomorrow.

Why we keep landing in this spot

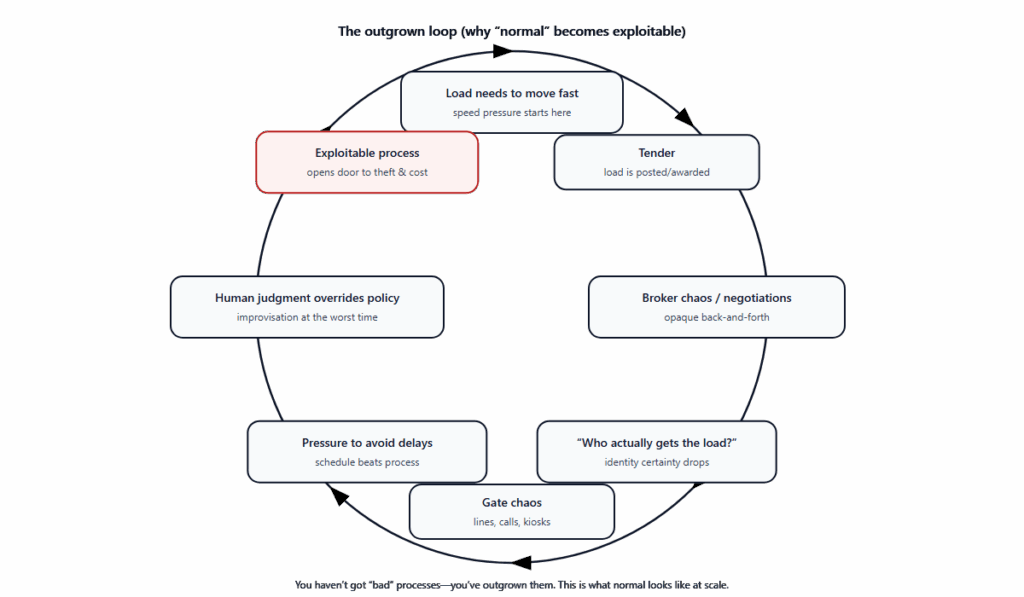

It’s not that we have “bad processes.” We’ve outgrown the ones that used to work. We digitized forms and added dashboards, but custody policy still lives in inboxes and calls. At today’s speed and scale, the pattern repeats:

None of that makes Lina negligent. It makes her normal, and normal is exactly what organized theft relies on. The loop doesn’t just waste minutes; it multiplies cost and risk. Inefficiency invites improvisation; improvisation creates openings; openings get exploited.

The real problem isn’t theft. It’s trust under pressure.

Strategic theft and operational leakage look like separate problems. They aren’t. Both emerge from the same root cause: trust breaks down when execution outruns verification.

We didn’t get here because people stopped caring. We got here because custody decisions are still resolved through inboxes, phone calls, and judgment calls: exactly where pressure is highest. Dashboards added visibility, not authority. Alerts added noise, not certainty.

That’s why the same moment (a busy gate, a delayed dock, a late tender) produces both outcomes:

- mistakes and inefficiency when people improvise, and

- exploitation when bad actors take advantage of that improvisation.

This is not a tooling gap. It’s an infrastructure gap.

Trust needs infrastructure, not supervision

True cooperation doesn’t come from tighter integrations or more alerts. It comes from credible enforcement. It comes from turning policy into mechanism.

When trust moves from “someone checked” to “the system enforces,” the problem changes. Decisions are resolved explicitly. Execution stays aligned across parties. And the equipment itself constrains what’s allowed to happen.

That’s what we mean by trust infrastructure, and it has three layers:

- Resolve — who is authorized to decide and approve changes, without ambiguity.

- Execute — how those decisions propagate across companies, yards, docks, and handoffs under pressure.

- Enforce — where custody and access are physically constrained, so out-of-policy actions are blocked, not debated.

When these layers are connected, trust stops being a leap of faith. It becomes part of how freight moves.

Where freight matching fits

Digital freight matching benefits enormously once trust is enforced. Markets clear efficiently when, identities are real, authorization is explicit, and execution doesn’t depend on last-minute judgment calls.

When policy lives on the trailer and execution aligns automatically, coordination costs fall. At that point, private, automated matching becomes viable as a byproduct of alignment.

A quick word on TSR (and how Admiral compares)

If TSR rings a bell: it’s the TAPA’s Trucking Security Requirements with 3 levels, the lowest of which allows self-certification, and the highest requires independent 3P audit. It’s focused on monitoring/response and documented procedures. Admiral trust infrastructure meets that bar and goes further by preventing out-of-policy events at the trailer itself (identity + time + location must align before access), which reduces the need to “chase” alerts after the fact.

Why this is safer (and calmer)

When policy lives on the trailer, the riskiest moment of the day is no longer the most chaotic. Lina doesn’t need to wave people through on faith. Steve doesn’t need to prove he’s not Bob. And the CFO doesn’t need paramedics on speed-dial.

Stay Connected

Want more insights like this? Follow Level5Fleet for future articles, freight industry trends, and updates on building a smarter, more secure supply chain:

🔗 LinkedIn

🐦 X: @Level5fleet

📘 Facebook

📸 Instagram

Trust Infrastructure for Freight