Admiral Lock Technical Manual

About This Manual

This manual provides installation, operation, storage, and transport guidelines for the Admiral Lock. Please read this manual carefully before installing and operating the Lock.

- Applicable Hardware Versions: Admiral Lock v1.3

- Intended Audience: Fleet managers and operators

- Purpose: Installation, operation, and safety guidelines for Admiral Lock

- Document Revision: 2025.03.20

- Support Contact: Contact Information and Support

Product Information

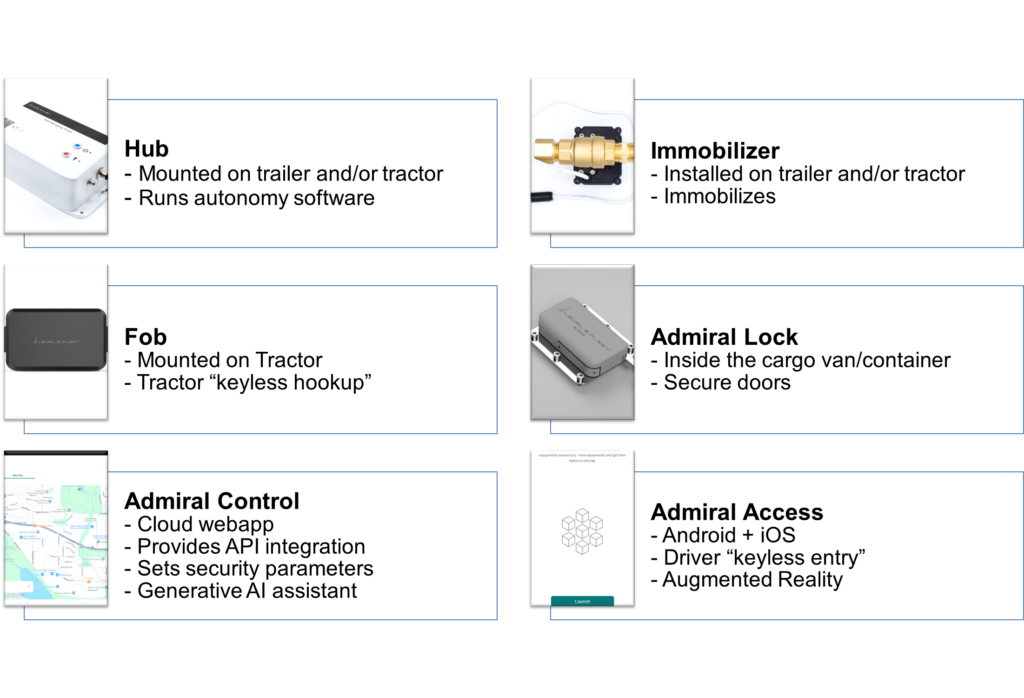

About Admiral Hub

The Admiral Lock is an integral component of Level5Fleet’s L4 autonomous security suite, designed to secure cargo doors on trailers, box vans and containers both in yards and during transit. Its robust design and interior installation ensure that it remains inaccessible to tampering, providing a high level of protection against unauthorized access.

The Lock can function as a standalone security device or in conjunction with the Admiral Hub. When paired with the Hub, it gains additional automation features, enabling automatic locking and unlocking based on geofencing. This ensures that security operations are seamlessly managed as assets enter or exit designated areas without requiring manual intervention.

Beyond securing cargo, the Admiral Lock enhances container tracking capabilities. When installed on Admiral-equipped containers and paired with an Admiral-equipped chassis, it enables real-time tracking of container movements. The system continuously records mounting, dismounting, and transfers between assets or vessels, ensuring a comprehensive log of container status throughout its journey.

Communication between the Admiral Lock and the Admiral Hub is established via Bluetooth. In standalone mode, WiFi connectivity allows for remote locking and unlocking, providing operators with greater flexibility. The Admiral Access mobile app further enhances accessibility by enabling users to securely open or close the Lock when in proximity.

For installations on swing doors, the Lock can detect whether the doors are open or closed, adding an extra layer of situational awareness. When installed within the frame, it can be paired with contact sensors to accurately monitor door positioning. These monitoring capabilities help reinforce security and automate the locking.

The Admiral Lock is dual powered, offering operational flexibility across varied scenarios. It is equipped with an internal battery that supports up to seven months of daily usage and can be easily replaced in the field with a fresh unit when depleted. For long-term storage applications, the battery maintains its charge for up to two years. Additionally, the Lock can be connected to the asset’s power supply to enable regular operation while also recharging the battery. In scenarios where battery usage is not desired, the Lock can also function exclusively using external power.

Safety Information

Warnings & Handling Instructions

- Use only the power supply cable shipped with the Lock.

- Connect only to 12V truck systems or approved adapters.

- Contains a Lithium battery – follow proper storage, transportation, and disposal procedures.

- The power switch must be OFF during storage and transportation.

- Do not use the Lock if:

- The security seal is broken.

- The enclosure is damaged.

Fire Protection

The Lock is powered by a 3-cell lithium-ion battery and is classified under UN3481 for transportation safety. To ensure safe handling during transit and storage, an external power supply switch is provided to electrically isolate the battery when not in use.

When external power is connected, the battery recharges automatically. The charging system is engineered with two independent, redundant safety circuits that protect against overcharging, undercharging, and short circuits. Additionally, battery monitoring adheres to the JEITA ET-5600 standard, providing temperature-based charge regulation for enhanced safety.

To reduce fire risk and preserve battery health, the Lock limits its charging current to 0.25C—a conservative rate that prioritizes safety over speed. While charging at this rate is slower, it significantly reduces thermal stress and extends battery life. A full recharge may take up to four hours under standard conditions.

Charging is disabled when the ambient temperature falls below 0°C (32°F) to prevent lithium plating and ensure long-term reliability.

Important: Only use power supplies and cables approved by Level5Fleet. Using unapproved accessories may lead to overheating or fire, resulting in damage to the Lock, the vehicle, cargo, and nearby equipment.

Jamming Risk Assessment

Due to its interior installation, the Admiral Lock carries a risk of access obstruction if mechanical jamming occurs. In rare cases, a shift in the door’s position can prevent the Lock from actuating properly, potentially leading to a lockout scenario. To mitigate this risk, fleet managers must ensure that standard exterior door locks are always used to prevent door movement while the asset is in motion or unattended. Additionally, it is essential that the Lock mounting bracket is installed with adequate clearance, allowing the doors to settle naturally into position without placing stress on the locking mechanism. The bracket must accommodate minor variations in alignment when doors are closed and external locks are engaged.

Under no circumstances should the Admiral Lock be used as the primary structural component to bear or support door loads. Dedicated lock brackets must always be used to isolate the Lock from mechanical strain.

The Lock includes integrated sensors that monitor its operation and surroundings. If the door is not fully closed, the bracket is misaligned, or the mechanism encounters physical obstruction, the Lock will halt operation and generate an alert to prevent damage or mis-actuation.

When operating on battery power alone, timely replacement of the battery is critical to ensuring uninterrupted functionality. The Metrics Dashboard provides proactive battery warnings. If the battery is not replaced in time, the Lock will automatically unlock to prevent access denial.

Operation of the Admiral Lock is not permitted at internal temperatures below -15°C. Integrated temperature sensors continuously monitor conditions, and the Lock will automatically inhibit actuation when operating below this threshold to prevent mechanical stress and ensure long-term reliability.

To safeguard against wear and overheating, the Lock also enforces rate-limiting protections. If more than five actuations occur within a one-minute window, a mandatory cool-down period of ten minutes is triggered. This mechanism is designed to prevent damage from excessive or improper use, ensuring continued reliability of the locking mechanism.

Admiral Lock also includes continuous health monitoring. Indicators of early mechanical or electrical failure are surfaced on the dashboard, giving operators time to take corrective action. If the Lock determines a high risk of malfunction, it will default to an unlocked state as a fail-safe measure, preserving access to the asset.

Breaching Risk Assessment

The Admiral Lock is engineered to withstand significant physical force, with a breach resistance rated at approximately five tonnes of force. This high-strength construction provides robust protection against forced entry attempts. However, optimal installation practices are critical to ensuring the Lock’s protective effectiveness in real-world scenarios.

To minimize the likelihood of successful breaches, the Lock should be mounted on the upper portion of the door, where it is more difficult for unauthorized actors to access or cut through the vehicle or container body. This placement reduces the feasibility of creating an access hole or manipulating the Lock from the exterior.

In high-risk environments, such as container operations with elevated smuggling concerns, additional precautions should be taken. It is common in such scenarios for bad actors to bypass seals by cutting door hinges rather than breaking the seal itself. To counter this tactic, it is strongly recommended to install two Admiral Locks—one on each door—positioned on opposite ends (one at the top and the other at the bottom). This configuration prevents the removal of doors without breaching at least one seal, thereby preserving the integrity of seal-based tamper detection systems.

By combining strategic placement with multiple locking points, fleet operators can significantly reduce vulnerability to advanced breaching attempts.

Product Identifications

FCC ID:

- 2AC7Z-ESPS3WROOM2

Lock ID:

The Lock ID is located under the Fleet Management Application in your Admiral Control Account. Login and navigate to Fleet Management, then select the asset to see Lock ID.

Technical Specifications

- Power supply: 12V, 2A DC

- Connectivity: 2.4G WiFi, Bluetooth LE

- Battery life: 7months (daily use), 2 years (storage)

- Charging time: 4 hours @ 2A

- IP rating: IP66

- Operating and Storage Temperature: -15°C to 55°C

Installation Guidelines & Operation

Admiral Lock supports multiple mounting configurations to accommodate different trailer, van and container door styles. A variety of purpose-designed brackets are available to ensure secure installation and proper alignment across all supported door types.

Door Types

Proper alignment and bracket selection are critical to reliable operation. Always ensure there is sufficient clearance and that brackets are mounted according to specifications for each door type to avoid jamming or misalignment during operation.

Swing Doors

For swing doors, the Lock can be mounted in several configurations depending on asset geometry and operational preferences. The most common setup involves mounting the Lock vertically, pointing upward, on the outer door—the one that interlocks with the other and must be opened first. The bracket is installed on the door frame near the center-top area to ensure secure engagement when the doors are closed.

Alternatively, the Lock may be mounted inside the door frame at the top, with the locking bolt oriented horizontally (left-to-right). In this configuration, a swing door bracket designed to align perpendicularly with the Lock when the door is closed must be used. This layout is particularly well-suited for assets where exterior mounting is not feasible or desirable.

For reefer trailers, the flat-profile of the Lock is designed to fit within the limited space between the refrigeration unit and the door. If the unit is positioned too close to the door to accommodate a vertical mount, the Lock may instead be installed horizontally, with the bracket attached to the opposite door for proper alignment.

Roll-Up Doors

For roll-up doors, the Lock should be installed on the side wall of the trailer body, just behind the vertical guide rails and near the lower section of the door. The locking bolt should face outward. The roll-up door bracket is mounted directly onto the roll-up door itself so that, when the door is closed, the bracket aligns precisely with the Lock’s bolt.

This position allows the door to rollup without the bracket interfering with the mechanism.

Side Sliding Doors

On side sliding doors, the Lock is installed on the trailer body just forward of the door opening, with the bolt facing upward. The sliding door bracket is affixed to the door such that when it is closed, the bracket sits directly over the Lock’s bolt, enabling secure engagement.

Operating Instructions

Operating instructions for the Admiral Lock are provided through Admiral Control’s Fleet AI Application. Fleet AI is a generative AI assistant designed to help you interact with and manage your Admiral system, offering tailored responses and step-by-step guidance based on your specific fleet configuration. It can assist with tasks related to fleet operations, security enforcement, and transportation management.

Fleet AI mirrors the functionality available through the traditional user interface, allowing you to complete the same actions more intuitively through conversational prompts.

To use Fleet AI, log in to your Admiral Control account and navigate to the Fleet AI section.

Lock Wake-Up Behavior

The Admiral Lock supports intelligent power management to balance accessibility with battery efficiency. Its wake-up behavior varies depending on the available power source and operational context.

When external power is connected, the Lock remains continuously awake. In this state, it is fully accessible via both the Admiral Access mobile app and remote systems through Admiral Control, enabling full remote management capabilities.

When operating solely on battery power, the Lock enters a low-power sleep mode during idle periods to conserve energy. While in sleep mode, remote access and remote wake-up are disabled. However, this is not a limitation in practice, as unlocking is typically performed by personnel on-site. The Lock can be woken in two ways: either through close-proximity interaction using the Admiral Access app or by detecting significant motion events, such as a container being lifted.

If the Lock is paired with an Admiral Hub, the Hub provides additional automation. Specifically, the Hub will wake the Lock automatically when entering or exiting designated geofenced areas, enabling autonomous locking and unlocking sequences without requiring user intervention.

Reliability Monitoring

The Lock includes embedded algorithms to continuously monitor the reliability. To enhance predictive diagnostics, the Lock collects and aggregates operational parameters from your fleet and, where applicable, from participating third-party fleets. This collective data improves the accuracy of reliability assessments across a wide range of operating conditions.

Monitored parameters include:

- Operating temperature trends

- Vibration profiles influenced by driving behavior and road surface conditions

- Actuation times of the lock

- Battery health indicators

- Total operation cycles

- Voltage and current consumption statistics

Using these insights, the system can identify signs of potential hardware degradation. When early indicators of failure are detected, you may receive a proactive notification through Admiral Control, allowing you to schedule hardware replacement before it affects fleet operations.

Metrics

Admiral Control provides a comprehensive monitoring dashboard through the Metrics & Reports Application. Security reports help identify and analyze trends related to loss prevention. Operational reports highlight recurring issues drivers face, such as denied access events, enabling fleet managers to refine workflows and improve employee experience.

Maintenance reports and associated trend analysis assist in forecasting maintenance needs and optimizing service schedules.

Troubleshooting

For issue resolution, use Admiral Control’s Fleet AI, which provides guided troubleshooting based on your specific fleet configuration. For issues not resolved through Fleet AI, contact Level5Fleet technical support.

Software Updates

The Lock receives software updates over the air (OTA), which require access to a configured WiFi network. When an update becomes available and the asset is idle within WiFi range, the Lock may automatically initiate the update process. A typical update takes approximately 10 minutes.

During updates, the door remains unlocked for safety.

To support planning, the maintenance dashboard highlights any Locks that are overdue for updates. Fleet managers should ensure these assets are within WiFi range during the next parked interval to complete the update.

Software Integration

For fleets using third-party Yard, Fleet, or Transportation Management Systems (YMS, FMS, TMS), Admiral supports seamless integration. You can generate an API integration key through the Account Management section of Admiral Control.

Privacy

Admiral enables you to transfer asset custody to or from other operators and to manage access permissions for third-party carriers and employees. By default, visibility across organizations is disabled, meaning other companies cannot grant you access unless explicitly allowed.

You can configure which external companies can view and interact with your organization for authorization purposes. These settings are managed within the Account Management section of Admiral Control.

Links

| Admiral Control | https://fa.level5fleet.com |

| Admiral Access | Google : Admiral Access – Apps on Google Play Apple: https://apps.apple.com/app/admiral-access/id6502579460 |

Trust Infrastructure for Freight